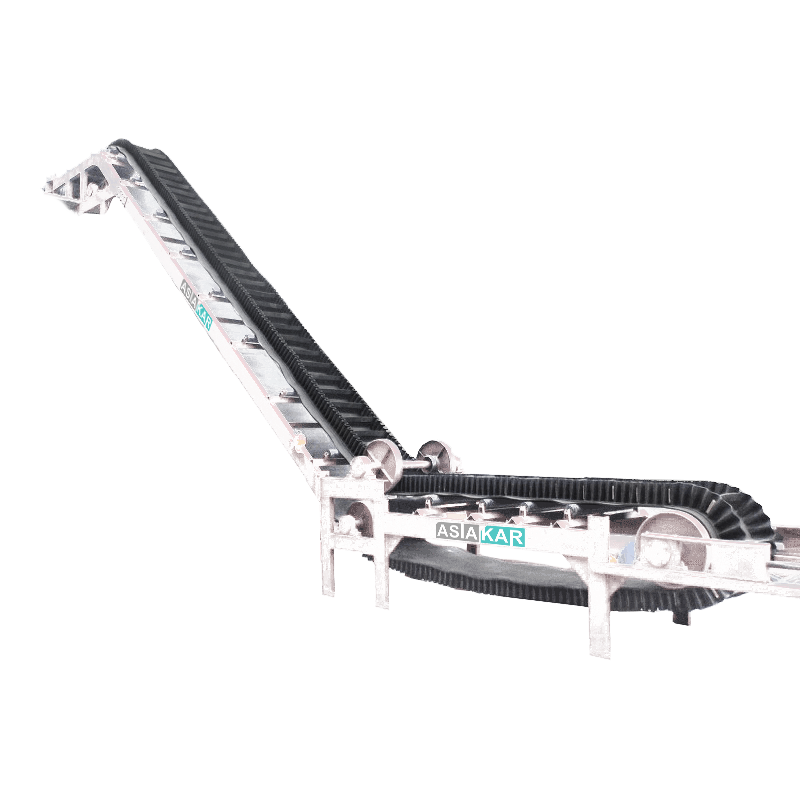

Sidewall Belt Conveyor

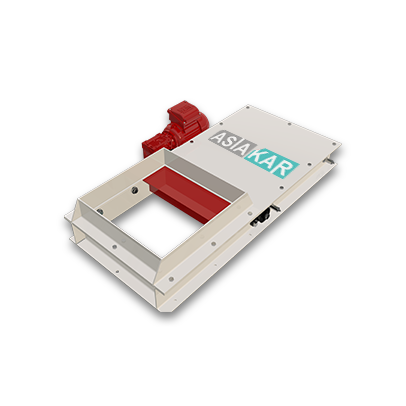

Z-Type Scraper Chain Conveyor

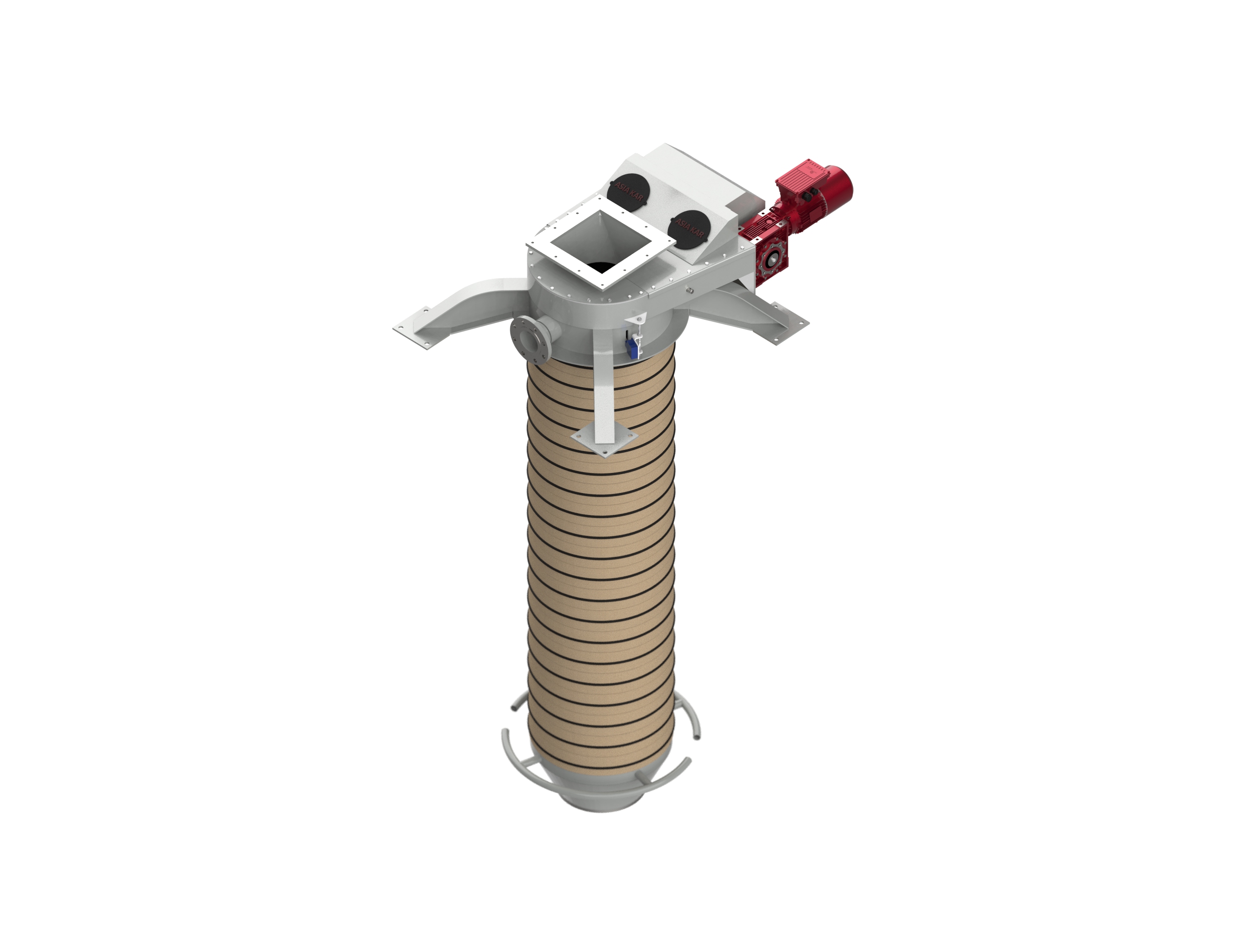

Air Cushion belt conveyor

Air Cushion belt conveyor that use rollers to support the conveyor belts have already been widely used in all industries, But the bearing form is intermittent contact bearing, which causes the vibration when conveying materials with bigger transportation resistance.

In order to overcome these shortages, Asiakar Co. Conveyor is devoted to researching new type belt conveyor, constantly launching Air Cushion Belt Conveyor.

Their common characteristics non-contact continuous bearing. An air-cushion conveyor is a kind of new-type and heavy-tank-type belt conveyor that can realize the large transport capacity.

explanation

This equipment can apply air cushion to replace the supporting roller bearing and change the rolling friction of supporting roller belt conveyor into fluid friction, as a result, it has reduced the tractive forces of driving device and the operation resistance of belt conveyor.Meanwhile, when there is the same transport capacity and conveying process, the power consumption is saved for 15-30% than the supporting roller belt conveyor.

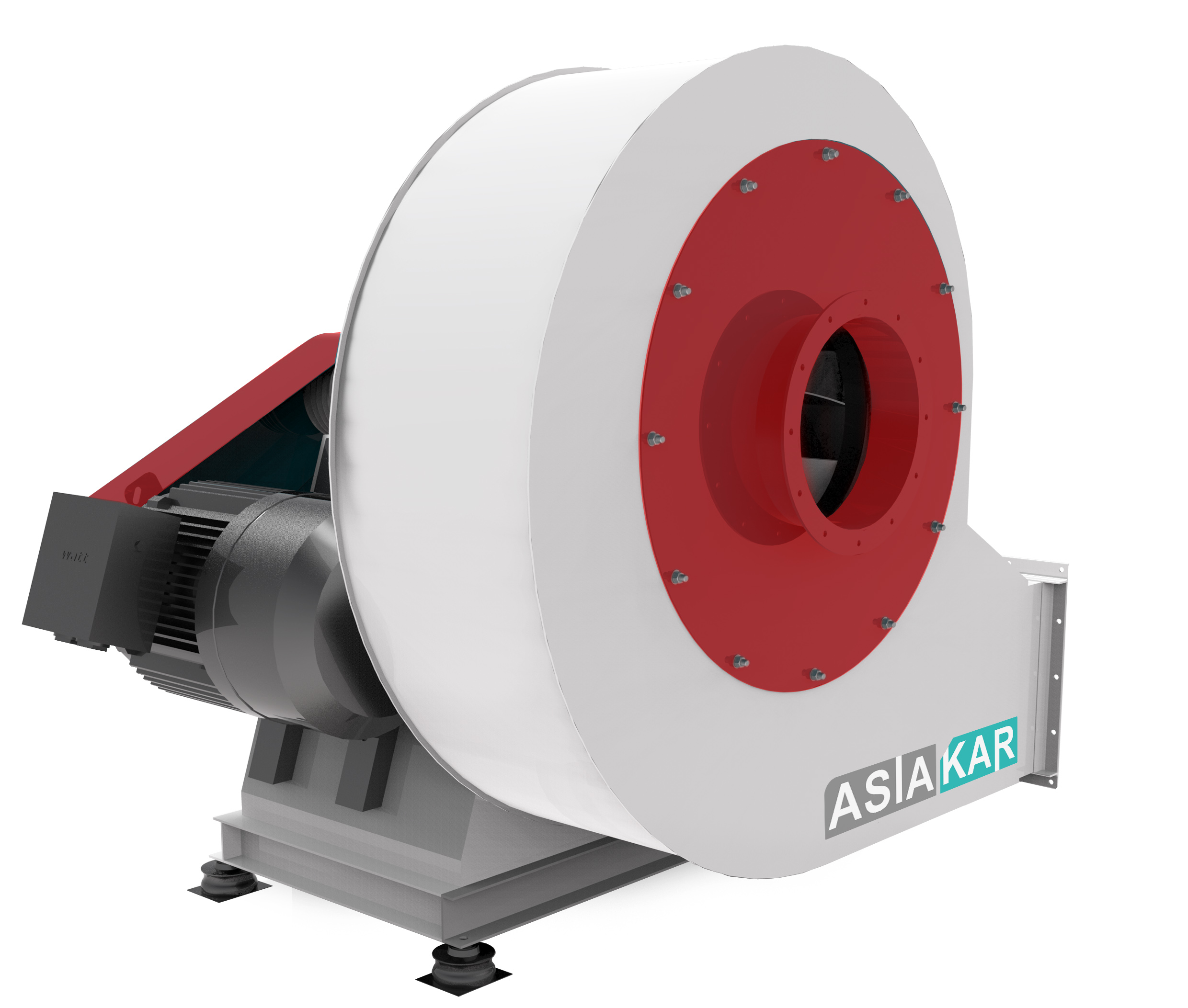

Apart from the part about air cushion formation, the structure of the Air Cushion Belt conveyor is similar with the one of general belt conveyor, that’s to say, contains the blower, connecting line, gas tank and so on, removing most of the bearing rollers.

Air cushion belt conveyor industrial uses

Asiakar Co. designs and manufactures Air Cushion Belt Conveyor to meet the needs of many industries, such as Steel Smelter Project / Cement industries / Nonferrous metal industries / Aluminum Smelter Project / Chemical Industries /Oil and Refining Industries / Minerals and mining Processing / Food industries / Wheat, Cereal and other grain silo/ Warehouse and silo Aeration Cycle Systems/grain silo and Warehouse equipment / Animal Feed Plants. foundry and transportation of bulk materials such as grain, salt, coal, ore, sand and etc.

This equipment can meet the transportation requirements for special materials. The blast capacity of the blower is enough to meet the air consumption of air cushion type belt conveyor and can fill the gas tank within several seconds to reach enough pressure intensity for forming air cushion.

Even if the materials on the belt are intermittent, the conveyor still works normally because pressure air always needs to expel from the air hole of the gas tank, without affecting the air cushion at the bearing point.

Because the pressure of air is bigger than the gravity of materials, with the addition that air has a certain speed, fine powder materials will not enter air cushion space for the gas tank and conveyor belt abrasion.

Moreover

This equipment can also adopt the closed circulating air chamber to meet the conveying requirements of toxic materials, such as the chemical field and medical industry, etc.This kind of Belt Conveyors are mainly used in the transmission of granular materials such as sand, stone, coal, iron ore, cement, clay, and many others also.

The Categories of these conveyors includes four types of full air cushion opening type, full air cushion sealing type, blending opening type, and blending sealing type.

We specialize in the design and manufacture of custom-built equipment that can immediately improve the safety, reliability, and efficiency of your order as your special material compared to other brands.

Asiakar Co. This equipment is custom designed for your application. Bulk material density, characteristics, Min. and Max. capacity, overall length and width and all the other detail components, devices, and standard parts are considered when designing Air Cushion Belt Conveyor Geared Motor Power (Kw), Geared Motor Speed (rpm), Centrifugal Fan Power.

All the equipment components and assembly of them (except the standard components and parts) are manufactured in our factory shop, with advanced, updated and high technology machines, equipment and devices by highly skilled craftsmen and they are manufactured with rigid quality standards.

CUSTOM ENGINEERINGEach application is unique with its own capacity requirements, location specifications and environmental needs. Asiakar Co. team of engineers considers these factors and more when designing each conveying system.Advantages Provided by Asiakar Co.Each application is unique with its own capacity requirements, location specifications and environmental needs. Asiakar Co. team of engineers considers these factors and more when designing each conveying system.The team of the Asiakar Co. engineers in cooperation with their counterparts of the host company, estimate the exact need of the site plant and determine the required capacity after a specialized visit from the relevant site plant.The team gathered environmental dimensional information on the existing equipment and facilities and tested the multiple material samples that are going to be conveyed while onsite.They determine accurate bulk densities and flow characteristics based on all gathered information. By considering all the observations and measurements, the team will recommend a new design as a solution that would not only handle current requirements but also provide additional life.Our engineers are available to assist you in every way possible to determine the best feeder design. Since the Air Cushion Belt Conveyor selected is based on a maximum volume control of material to be handled, surge loads, overloads and choke feeding, must be accounted for in the Air Cushion Belt Conveyor design.

360 degree view

Specifications

Surface coating specifications

Epoxy paint contains Zinc Rich , Sa 2½

Ability to install PLC system

Possible

Power transmission method

Direct coupling

Gear motor chassis

Allocated

Ability to carry materials

Powdery material

Landing conditions

Disassembled

Leave your material handling systems to us