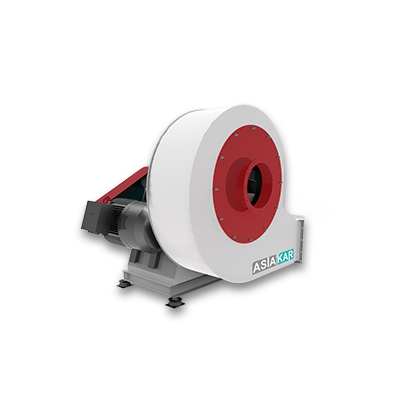

Centrifugal Fan

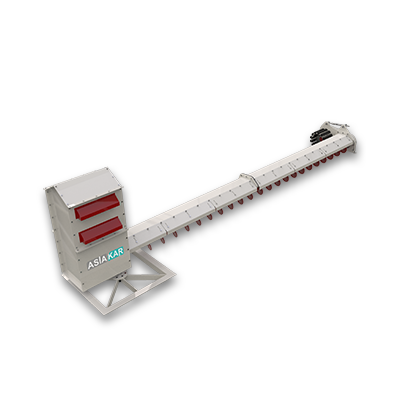

Sweep Auger

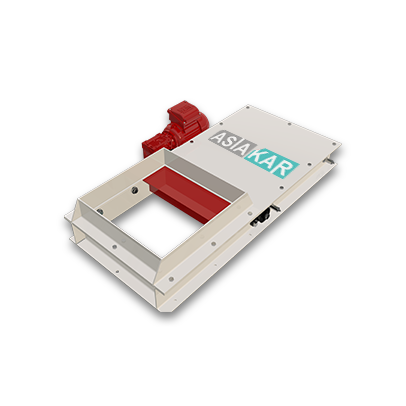

A Slide Gate is a kind of industrial discharge Gate equipment that is multi-functional and used as locking, metering and safety components below dosing and in process engineering systems of the bulk material technology.

Asiakar Co. designs and manufactures Slide / Discharge Gate to meet the needs of many industries, such as Steel Smelter Project / Cement industries / Nonferrous metal industries / Aluminum Smelter Project / Chemical Industries / Oil and Refining Industries / Minerals Processing / Food industries / Wheat, Cereal and other grain silo/grain silo and Warehouse equipment / Animal Feed Plants.

Slide gates are a reliable way to control the flow of powders, granules or solids from hoppers to other system components the same as conveyors and are put to use where materials must be transported in or out or where the flow rate must be limited.

We specialize in the design and manufacture of custom-built equipment that can immediately improve the safety, reliability, and efficiency of your order as your special material compared to other brands.

This equipment is designed and manufactured in two types of the manual ( which is opened and closed by chains) and electrical and automatic (which is opened and closed by Geared Motor or Pneumatic Cylinders which can be connected to the plc systems and sensors).

Slide Gate Industrial uses

Asiakar Co. Automatic Slide Gates are custom designed for your application. Bulk material density, characteristics, Min. and Max. capacity, overall length and width and all the other detail components, devices, and standard parts are considered when designing Screw Conveyor Geared Motor Power (Kw) and sliding movement Speed (m/s) for gate opening and closing.

All the equipment components and assembly of them (except the standard components and parts) are manufactured in our factory shop, with advanced, updated and high technology machines, equipment and devices by highly skilled craftsmen and they are manufactured with rigid quality standards.

Our slide gate series is made for extreme and complicated operating conditions. They can be easily affixed or removed. Slide in the gate moves on the ball bearings and opens or closes the grain flow way.

Moreover slide gates can be used to relieve the load on subsequent hauling equipment such as Screw and Chain Conveyors, belt conveyors, or rotary valves.

Advantages Provided by Asiakar Co.

The team of the Asiakar Co. engineers in cooperation with their counterparts of the host company, estimate the exact need of the site plant and determine the required capacity after a specialized visit from the relevant site plant.

The team gathered environmental dimensional information on the existing equipment and facilities and tested the multiple material samples that are going to be conveyed while onsite. They determine accurate bulk densities and flow characteristics based on all gathered information.

By considering all the observations and measurements, the team will recommend a new design as a solution that would not only handle current requirements but also provide additional life.